Superbolt® Expansion Bolts replace large fitted or interference fit bolts, no modifications required.

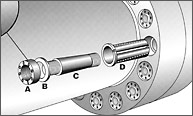

EB's utilize a six piece system. The small end Torquenut® supplies the large force required to draw the tapered stud into the expandable tapered sleeve. As the tapered sleeve expands, a large radial force is exerted in the coupling through holes. The large end Torquenut creates additional clamping force on the joint and is also used for easy removal of the tapered stud. Once the tapered stud is extracted, the sleeve collapses for easy removal.

Benefits:

• Easy: Loose fit sleeves (up to .010" - .020" in the through-hole) are easily inserted even in holes misaligned due to rotation. Some other systems require time and expense of separate alignment tools. Only hand tools are required for installation and removal.

• Fast: Tightening requires less than 5 minutes per assembly.

• Safe: Eliminates the need for special high powered tools, bolt heaters and high pressure hydraulic systems. Torque required is usually under 100 ft-lbs.

• Economical: Save 50% or more over hydraulic systems. Additionally, for precise alignment only four Expansion Bolts are needed. Loose fit through-bolts with Torquenuts, can be used in the remaining holes.

• Reusable: The Split sleeve springs back to original size, use after use. Compared to the close tolerance solid sleeves found in other systems, the loose fit split sleeve is much less likely to hang up during removal.

• Generates axial and radial force simultaneously. Easier to "pull together" coupling halves.

• No honing required: Only line boring of holes is necessary.

• No coupling face machining is required (where the nuts seat). The multi-jackbolt design compensates for small variations in perpendicularity of the spotface to the hole centerline.

• Eliminate finish machine of sleeves on site: Generous sleeve expansion permits finish machining in advance.

Applications

• Steam, Gas, & Hydro Turbines

• Large Motor Couplings

• Marine Drives

• Ring Gears

• Split Gears

• Flanges - alignment tool

How it works

Installation:

1) Insert expandable tapered sleeve (D) into through-hole.

2) Insert tapered stud (C) into tapered sleeve.

3) Slip washer (E) over threaded small end of tapered stud.

4) Thread Torquenut (F) onto small end of tapered stud.

5) Tighten set screws on Torquenut (F) to prescribed torque.

6) Install washer (B), Torquenut (A), and tighten set screws.

Removal:

Removal is as simple as loosening Torquenut (F) and extracting the stud with Torquenut (A). Once the tapered stud is extracted, the sleeve collapses, allowing easy removal.